Predictive Maintenance Explained: Types, Uses & Examples

Discover how predictive maintenance explained helps you predict equipment failures, cut costs, & boost uptime. Explore types, tech, & real examples.

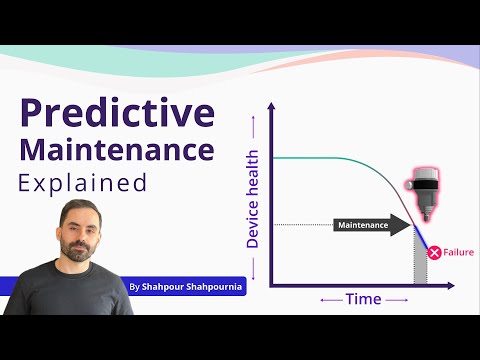

Predictive maintenance monitors your equipment while it runs and uses that data to predict when something will break before it actually fails. Instead of fixing machines on a schedule or waiting for them to stop working, you watch for warning signs like unusual vibrations, temperature changes, or performance drops. When sensors detect these patterns, you know maintenance is needed and can plan repairs at the right time.

This guide breaks down everything you need to understand about predictive maintenance. You'll learn why it matters for your operations, the specific technologies that make it work, and how to set up a program from scratch. We cover the different types of predictive maintenance, show you real examples from multiple industries, and explain how it compares to other maintenance approaches. You'll also discover the common mistakes that trip up most implementations and how to avoid them. Whether you run BioGas processing equipment or any other industrial machinery, these insights help you reduce downtime and cut maintenance costs.

Why predictive maintenance matters

Predictive maintenance matters because it transforms your maintenance budget from a reactive expense into a strategic advantage. You stop wasting money on unnecessary scheduled repairs and eliminate the massive costs that come with unexpected equipment failures. Industrial manufacturers report 25-30% lower maintenance costs and 70-75% fewer equipment breakdowns after implementing predictive maintenance programs. Your operations run smoother because you fix problems during planned windows instead of dealing with emergency shutdowns that halt production.

Lower costs and higher uptime

You reduce downtime by catching failures early, which directly impacts your bottom line. Unplanned downtime costs manufacturers an estimated $50 billion annually, with equipment failure causing 42% of these disruptions. When you implement predictive maintenance, you schedule repairs during off-peak hours or planned maintenance windows. This approach means your production lines keep running when demand is highest, and you avoid paying premium rates for emergency repairs or rush-ordered replacement parts.

Predictive maintenance typically delivers a 5-10% reduction in overall maintenance costs and a 5-10% decrease in operations and maintenance spending.

Better resource planning

Your maintenance team works more efficiently when they know exactly what needs attention and when. Predictive maintenance gives you 2-4 weeks of advance warning before most failures occur, so you order parts ahead of time and schedule technicians properly. You eliminate the guesswork that leads to overstocking spare parts or running out of critical components. This planning advantage extends your equipment lifespan by 35-45% because you address small issues before they cause catastrophic damage.

How to implement predictive maintenance

You build a successful predictive maintenance program through a structured approach that starts with understanding your current operations and gradually adds monitoring capabilities. Your first step involves identifying which equipment deserves predictive monitoring based on factors like replacement cost, criticality to production, and failure consequences. Not every machine needs the same level of attention, so you prioritize assets where unplanned downtime creates the biggest financial impact or safety risk. This targeted approach keeps your initial investment reasonable while delivering immediate value from your most critical equipment.

Start with equipment assessment

You evaluate each piece of equipment against specific criteria to determine monitoring priorities. Focus on machines where failure would halt production, endanger workers, or cost more than $10,000 to replace. Your assessment should document current maintenance costs, failure history, and the impact each breakdown has on operations. Calculate the annual downtime hours for each asset and the revenue lost during those periods. This data helps you build a business case for predictive maintenance and shows exactly where you'll see returns first. Equipment that runs continuously or operates in harsh conditions typically ranks highest for predictive monitoring because it faces greater wear and more frequent failures.

Set up monitoring infrastructure

Installing sensors and data collection systems forms the foundation of your predictive maintenance program. You need sensors that match the specific failure modes you're trying to catch, whether that's vibration monitors for rotating equipment, thermal cameras for electrical systems, or pressure sensors for hydraulic components. Start with one or two equipment types rather than attempting to monitor everything at once. Your sensors must connect to a central system that stores and processes the data they generate, which could be cloud-based software or an on-premise solution depending on your IT infrastructure and security requirements.

Once predictive maintenance is explained and implemented properly, most programs show measurable results within the first 6 months of monitoring critical equipment.

Establish baseline performance metrics

You create reference points by monitoring equipment during normal operation before setting alert thresholds. Collect at least 30 days of operational data when your machines run properly to understand typical vibration levels, temperature ranges, and performance characteristics. This baseline data tells you what normal looks like so you can identify when conditions start to drift toward failure. Different operating modes require separate baselines, so you document performance during startup, full load, and shutdown cycles. Your baseline becomes the standard against which all future measurements are compared, making it the most critical step in accurate prediction.

Create response protocols

Defining clear actions for each alert type ensures your team responds appropriately when the system detects problems. You need documented procedures that specify who gets notified, what inspections to perform, and when to schedule repairs based on alert severity levels. A minor temperature increase might trigger weekly monitoring, while severe vibration spikes demand immediate inspection and potential shutdown. Your protocols should include parts ordering procedures, approved repair methods, and escalation paths for situations where the detected condition worsens faster than expected. Train your maintenance team on these protocols before going live so everyone understands their role when alerts occur.

Key technologies and data sources

You rely on a combination of hardware and software tools that work together to capture, analyze, and interpret equipment data. Predictive maintenance systems start with sensors that monitor physical conditions, then feed that information into processing platforms that identify patterns and predict failures. Your technology stack needs to handle real-time data collection, storage of historical records, and advanced analytics that turn raw measurements into actionable maintenance decisions. The specific technologies you choose depend on your equipment types, failure modes, and existing IT infrastructure.

Sensor types and monitoring equipment

Your sensors form the eyes and ears of your predictive maintenance program by measuring conditions that indicate equipment health. Vibration sensors detect imbalance, misalignment, and bearing wear in rotating machinery like pumps, motors, and compressors. Temperature sensors spot overheating in electrical systems, friction problems in mechanical components, and cooling system failures before they cause damage. Acoustic monitors pick up ultrasonic frequencies from air leaks, steam leaks, and bearing defects that human ears cannot hear. You also use pressure sensors for hydraulic systems, oil analysis sensors for contamination detection, and current sensors for electrical motor condition monitoring. Each sensor type targets specific failure modes, so you match the monitoring technology to the problems most likely to occur in your equipment.

Data collection and processing systems

Your data infrastructure connects sensors to analysis tools through edge devices, gateways, and cloud platforms. Edge computing devices process sensor data locally and filter out noise before transmission, reducing bandwidth requirements and enabling faster response times for critical alerts. Gateway devices aggregate data from multiple sensors and translate different communication protocols into a standard format your central system can understand. Cloud platforms from providers like Microsoft Azure or Amazon Web Services offer scalable storage and computing power for analyzing large datasets from multiple facilities. Your system needs to handle both streaming real-time data for immediate alerts and historical data storage for trend analysis and machine learning model training.

Modern predictive maintenance systems process millions of data points daily, turning raw sensor readings into clear maintenance recommendations.

Analytics and machine learning tools

Your analytics layer transforms collected data into failure predictions through statistical analysis and artificial intelligence. Machine learning algorithms learn normal operating patterns from historical data, then flag deviations that indicate developing problems. You use rule-based analytics for simple threshold monitoring, statistical process control for trend detection, and neural networks for complex pattern recognition across multiple variables. These tools calculate remaining useful life estimates, prioritize maintenance tasks by urgency, and recommend specific corrective actions. Your analytics platform should integrate with your computerized maintenance management system (CMMS) to automatically generate work orders when predictive maintenance explained thresholds are exceeded, creating a seamless flow from detection to repair.

Types of predictive maintenance

You approach predictive maintenance through different methodologies that suit various equipment types, failure modes, and operational requirements. Each type uses distinct data analysis techniques to predict failures, ranging from simple threshold monitoring to complex artificial intelligence algorithms. Your choice depends on factors like equipment criticality, available data, and the predictability of failure patterns. Understanding these types helps you select the right approach for each piece of equipment in your facility, ensuring you get maximum value from your monitoring investments.

Condition-based monitoring techniques

You monitor specific equipment parameters against preset thresholds to trigger maintenance actions when conditions deteriorate. This approach tracks measurements like vibration levels, temperature, pressure, or oil contamination and compares them to established limits that indicate acceptable operation. When readings exceed your defined thresholds, the system alerts your maintenance team to investigate and schedule repairs. Condition-based monitoring works best for equipment with well-understood failure modes where the relationship between measured conditions and failure risk is clear and documented. For example, you might set a vibration threshold at 0.3 inches per second for a pump bearing, knowing that readings above this level indicate wear that will lead to failure within weeks if left unaddressed.

Statistical trend analysis

Your trend analysis examines how equipment conditions change over time to predict when failures will occur. You collect continuous measurements and analyze the rate of change rather than just absolute values, which gives you earlier warning than simple threshold monitoring. This type identifies gradual degradation patterns like bearing wear that produces steadily increasing vibration or insulation breakdown that causes slowly rising motor temperatures. Statistical methods like linear regression, exponential smoothing, and control charts help you calculate remaining useful life and schedule maintenance before conditions reach critical levels. Trend analysis proves especially valuable when predictive maintenance explained for equipment with long degradation cycles, where changes happen slowly enough that point-in-time threshold checks might miss developing problems.

Statistical trend analysis typically provides 2-4 weeks more advance warning than simple threshold monitoring for gradual failure modes.

AI and machine learning methods

You leverage artificial intelligence to detect complex patterns across multiple sensors and predict failures that single-variable monitoring would miss. Machine learning algorithms analyze thousands of data points simultaneously, identifying subtle correlations between temperature, vibration, pressure, and performance metrics that indicate specific failure types. Neural networks learn from your historical failure data to recognize the unique signatures that precede breakdowns, even for equipment with unpredictable or complex failure modes. This approach continuously improves its accuracy as it processes more data, adapting to your specific operating conditions and equipment configurations. You benefit most from AI methods on critical equipment where traditional monitoring falls short, such as gas processing systems where multiple interacting variables determine component health and failure timing depends on complex environmental and operational factors.

Predictive vs preventive and other methods

You choose between maintenance strategies based on equipment criticality, failure patterns, and cost considerations. Predictive maintenance monitors condition in real-time and schedules work when data indicates a problem, while other methods follow fixed schedules or respond to failures after they occur. Your decision impacts both operational costs and downtime, since each approach serves different equipment types and risk profiles. Understanding these differences helps you apply the right strategy to each asset rather than forcing a one-size-fits-all solution across your entire facility.

How preventive maintenance differs

Preventive maintenance schedules repairs at regular intervals regardless of actual equipment condition. You perform maintenance based on calendar dates, operating hours, or production cycles rather than monitoring for signs of wear or degradation. This approach proves simple to implement because it requires no sensors or condition monitoring systems, just a basic schedule and compliance tracking. Preventive maintenance costs more than predictive maintenance explained methods because you replace parts that still have useful life remaining and might perform unnecessary service on equipment that hasn't degraded. Your maintenance team follows manufacturer recommendations or historical averages to set intervals, which means some machines receive too much attention while others fail between scheduled services.

Preventive maintenance typically costs 30-40% more than predictive maintenance while still allowing 25-30% of equipment failures to occur between scheduled services.

Reactive and corrective approaches

Reactive maintenance waits for equipment to fail before performing repairs, making it the least expensive strategy upfront but most costly long-term. You fix problems only when breakdowns occur, which means no investment in monitoring systems or scheduled maintenance programs. This method suits non-critical equipment where failures cause minimal production impact or safety risk. Corrective maintenance addresses known defects identified through inspections but not yet causing operational problems, creating a middle ground between reactive and preventive approaches. Both strategies accept higher failure rates and emergency repair costs in exchange for lower maintenance labor and simpler planning requirements.

Predictive maintenance examples and use cases

You see predictive maintenance delivering measurable results across diverse industries, from manufacturing plants to energy facilities. Real-world implementations demonstrate how condition monitoring prevents failures, reduces costs, and improves safety in operations ranging from small-scale equipment to massive industrial systems. These examples show you specific applications and the outcomes organizations achieve when they monitor equipment health rather than following fixed maintenance schedules. Your own operations likely face similar challenges, making these cases directly relevant to your facility planning and equipment management decisions.

Manufacturing and production facilities

Your manufacturing operations benefit from predictive maintenance through early detection of mechanical failures that halt production lines. Automotive plants use vibration monitoring on spot-welding guns that perform 15,000 welds daily, connecting these tools globally to collect millions of data points that predict when electrodes need replacement. This approach prevents defective welds from reaching customers and eliminates production delays from unexpected welding equipment failures. Domestic appliance manufacturers monitor drum rotation vibrations in dryer production lines, which has eliminated 33% of manufacturing defects and reduced consumer warranty claims by 27% through early detection of assembly problems.

Steel processing facilities apply anomaly detection to cold-rolling equipment by tracking vibration, rotational speed, and electrical current in real time. These implementations extended equipment lifetime by 60% and dramatically reduced losses from unplanned downtime. Your production team gains similar advantages by monitoring critical machinery that directly impacts product quality or throughput, focusing efforts on assets where failures create the longest recovery times or highest scrap rates.

Energy and utilities operations

Your energy infrastructure demands high reliability since equipment failures affect thousands of customers and create significant financial penalties. Power companies monitor transformer temperatures, oil quality, and load characteristics to prevent outages that cost millions in compensation payments and drive customers to competitors. Utilities deploy predictive maintenance on distribution networks using drones and sensors that map equipment conditions across vast service territories, identifying failing components before they cause blackouts.

Energy sector implementations of predictive maintenance explained methodologies have reduced facility downtime by 5-15% while increasing labor productivity by up to 20%.

BioGas processing facilities monitor compressor vibrations, heat exchanger performance, and valve conditions to maintain continuous operation and prevent contamination issues that compromise biomethane quality. Your energy systems benefit from thermal imaging on electrical panels to catch overheating connections, acoustic monitoring for leak detection in pressure vessels, and oil analysis on hydraulic systems that control critical processes. These monitoring approaches prevent the cascading failures that turn single component problems into facility-wide shutdowns.

Transportation and logistics

Railroad operations use predictive maintenance to ensure passenger safety and minimize service disruptions that affect thousands of travelers. Track monitoring systems in train cabs detect voids under rails through continuous measurements of multiple variables, providing both void location and severity ratings. This technology prevents derailments by identifying structural problems before tracks fail under normal traffic loads. Railway companies also monitor wheel bearings, braking systems, and electrical components on rolling stock to schedule repairs during planned maintenance windows rather than responding to breakdowns that strand passengers.

Fleet management operations track vehicle engine performance, transmission conditions, and brake wear across hundreds of trucks or delivery vehicles. Your logistics operation reduces roadside failures and extends vehicle service life by monitoring diagnostic codes, fuel efficiency changes, and component temperatures that indicate developing mechanical problems.

Oil and gas industry

Your upstream and downstream operations handle high-value equipment in remote locations where failures create safety risks and production losses. Oil field operators monitor pump vibrations, motor temperatures, and flow rates across distributed assets, using wireless sensors to track equipment that traditional inspection methods cannot reach efficiently. Drilling operations apply predictive maintenance to detect bearing wear in top drives and kelly drives, preventing failures that halt expensive drilling programs and risk wellbore integrity.

Refining facilities monitor rotating equipment like compressors and turbines that process millions of dollars of product daily, applying vibration analysis and thermal imaging to catch problems weeks before failures occur. Your processing equipment faces similar wear patterns and benefits from condition monitoring that identifies seal leaks, bearing degradation, and alignment issues before they cause unplanned shutdowns or product contamination incidents.

Common challenges and how to avoid them

You face several obstacles when implementing predictive maintenance, but understanding these barriers ahead of time helps you avoid the mistakes that derail most programs. The most common problems involve data quality, initial investment costs, and organizational resistance rather than technical limitations of the monitoring equipment itself. Your success depends on addressing these challenges systematically instead of hoping they resolve themselves as your program matures. Planning for these issues during your implementation phase saves months of troubleshooting and prevents the program stalls that cause management to question the investment.

Data quality and integration issues

Your predictive maintenance program fails when sensors generate inaccurate data or systems cannot communicate with each other. Poor sensor placement produces misleading readings that trigger false alarms, eroding trust in the system and causing your team to ignore legitimate warnings. You prevent this by following manufacturer installation guidelines exactly and validating sensor accuracy during commissioning with handheld instruments. Integration challenges arise when your monitoring platform cannot connect to existing maintenance management systems, forcing manual data transfer that slows response times and introduces errors. Select platforms with pre-built connectors to your CMMS and ERP systems, or budget for custom integration work before you start collecting data.

Organizations that establish data governance programs backed by key stakeholders experience 60% fewer data quality issues during predictive maintenance implementations.

Cost and resource constraints

Your upfront investment in sensors, software, and training appears expensive when compared to reactive maintenance that requires no monitoring infrastructure. You justify these costs by calculating the annual losses from unplanned downtime and emergency repairs, showing management the financial impact of equipment failures over a three-year period. Start small by monitoring your three most critical assets rather than attempting facility-wide coverage immediately. This approach proves the value of predictive maintenance explained through quick wins while keeping initial spending manageable. Your limited maintenance staff gains capacity through better planning rather than facing additional workload, since predictive insights replace time-consuming inspections and reduce emergency response demands that pull technicians from scheduled work.

Key takeaways

Predictive maintenance explained simply means monitoring equipment conditions to schedule repairs before failures occur, replacing reactive fixes and time-based schedules with data-driven decisions. You gain 25-30% lower maintenance costs and 70-75% fewer breakdowns by catching problems early through sensors, analytics, and real-time monitoring. Your implementation starts with assessing critical equipment, installing appropriate sensors, establishing performance baselines, and creating clear response protocols that turn alerts into action.

The technology stack combines vibration sensors, thermal cameras, acoustic monitors, and AI-powered analytics that process millions of data points into maintenance recommendations. You choose between condition-based monitoring, statistical trend analysis, or machine learning methods based on your equipment types and failure patterns. Common challenges like data quality issues and integration problems get solved through proper planning, phased rollouts, and strong management support.

Your BioGas processing systems benefit from these same predictive maintenance principles to ensure continuous operation and optimal performance. Equipment designed with maintenance efficiency in mind reduces your operational costs while maximizing uptime. Learn how 99pt5's BioTreater™ system delivers industry-leading reliability with guaranteed performance and minimal maintenance requirements.